Student welds a solution

Published 6:00 am Tuesday, February 9, 2021

|

Getting your Trinity Audio player ready...

|

A Buckingham welding student has helped to make a safe return to school possible for his peers thanks to some hard work and ingenuity.

William Scharer, 17, has attended Buckingham County Public Schools (BCPS) his whole life. Now a senior in high school, Scharer is a part of Buckingham Welding Instructor Chris Walter’s advanced Welding III course at the Buckingham County Career and Technical Center.

Like many schools, BCPS students had to adapt to an all-virtual learning environment last semester due to the COVID-19 pandemic. During the fall, school officials were developing a plan to get students back in the classroom safely, and part of that plan included plexiglass desk shields for the high school and career tech buildings.

The shields were a must-have in order to bring students back, but the brackets the school needed to purchase in order to install the shields were going to be very expensive. That’s when the welding department was approached by the administration for help.

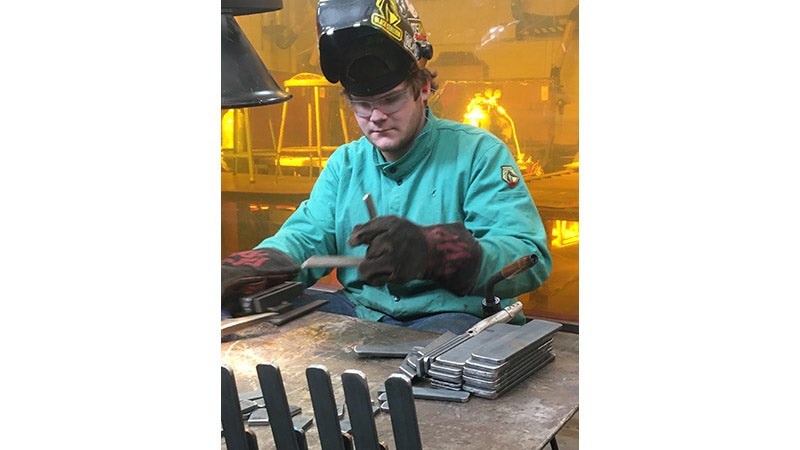

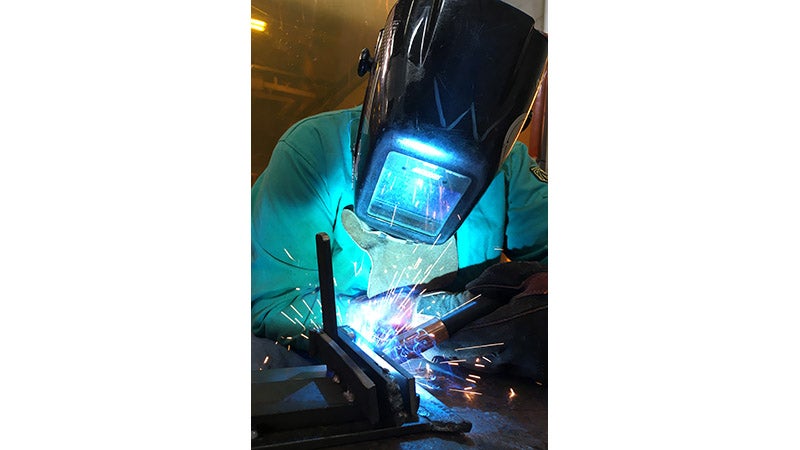

Walter and Scharer immediately began the process of sketching, designing and fabricating a prototype bracket. Once the concept was approved, a material jig was designed and constructed that would allow for 100 metal brackets to be fit and welded into 50 sets for holding each plexiglass desk shield.

Normally, students in Welding III would spend one hour in the shop each day for about four or five days a week. However, due to the COVID-19 pandemic, Scharer has instead been coming into the shop for four straight hours of welding time once a week.

In order to make the brackets, Scharer spent approximately 12 hours in the shop prepping the metal and fabricating, welding and cleaning the brackets, including his regular shop time and extra time on the weekend.

Saturday, Jan. 30, the final brackets were completed and ready to be implemented throughout the school.

Walter, who has been teaching at the career and technical center since 2016, said students in Welding III spend the majority of their class time honing the welding skills they have developed over the last two courses, from theory to execution.

For Walter, Scharer’s hard work on the project is a testament to the welding student’s unselfish nature and willingness to serve others without delay.

He said Scharer is an exemplary student who embodies all of the qualities one would wish to find in a young welder, from a high skill level to unwavering focus, dedication and a strong academic drive.

For Scharer, the project served as an opportunity to play his part in getting school life back to a new normal.

“I like helping with school any way I can, especially to help get us back in school, and I feel like everybody could help in a way if they just find the right thing to do.”

After graduating, Scharer plans to stay in welding and is hoping to apply to an apprentice school for a shipyard welding program.

Buckingham County Career and Technical Center Principal Kyle Bryan expressed his pride in the department’s efforts.“It did save the school quite a bit of money, but I think it also gave Mr. Scharer and Mr. Walter both a sense of accomplishment and helping through this pandemic,” he said.

“We’ve had a whole lot of firsts, a whole lot of things we’ve had to contend with this year that we never have had to do before. A lot of people here have pitched in and helped to try to pull it all together and make it work.”